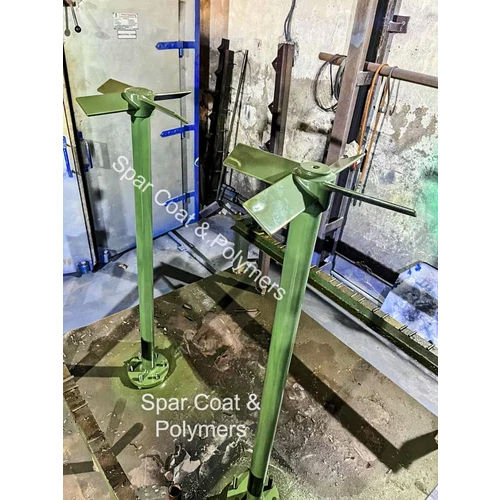

Antistatic Halar Coating Services On Filters

Antistatic Halar Coating Services On Filters Specification

- Coating Material

- Halar (ECTFE)

- Maximum Operating Temperature

- Up to 150C

- Environmental Compliance

- Meets RoHS and REACH standards

- Antistatic Property

- Yes

- Curing Process

- Thermal curing at specified temperatures

- Product Name

- Antistatic Halar Coating Services On Filters

- Surface Finish

- Smooth and uniform

- Packaging After Coating

- Protected with anti-scratch and dust-proof covers

- Surface Preparation

- Sandblasting or chemical cleaning prior to coating

- Thickness of Coating

- 20120 microns

- Service Mode

- Offline / Onsite

- Corrosion Resistance

- High

- Color

- Green or as required

- Filter Compatibility

- Suitable for metal and non-metal filters

- Chemical Resistance

- Excellent

- Customization

- Thickness and finish can be customized

- VOC Emission

- Low VOC release during application

- Adhesion

- Strong adhesion to metal filter surfaces

- Service Industries

- Pharmaceutical, Chemical, Food Processing, Electronics

- Coating Type

- Electrostatic spray coating

- Turnaround Time for Service

- Typically 37 days

- Application

- Antistatic coating for filters

- Shelf Life of Coated Filters

- Up to 5 years depending on operating conditions

- Electrical Conductivity

- Antistatic surface prevents static buildup

- Durability

- Long-lasting performance in industrial environments

Antistatic Halar Coating Services On Filters Trade Information

- Minimum Order Quantity

- 1 Square Feet

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About Antistatic Halar Coating Services On Filters

For a limited time, utilise our acclaimed Antistatic Halar Coating Services On Filters, designed for monumental industrial standards. Experience immaculate filtering precision and remarkable durability thanks to Halar (ECTFE) coatings, exhibiting superb chemical resistance and antistatic properties. This service is ideal for pharmaceutical, chemical, food processing, and electronics sectors. Customizable thickness and finish, low VOC emissions, and compliance with RoHS/REACH ensures both performance and environmental responsibility. Our rapid turnaround time of 3-7 days and strong adhesion guarantee reliability, while coated filters enjoy a shelf life of up to 5 years. Secure your offer now!

Antistatic Halar Coating Services: Where Precision Meets Performance

Our coating services are indispensable across pharmaceutical, food processing, chemical, and electronics industries for their exemplary protection against static and corrosion. The process leverages advanced electrostatic spray machines with thermal curing, resulting in a smooth, uniform finish and impeccable adhesion. Special features include remarkable durability at temperatures up to 150C and strong performance on both metal and non-metal filters. Count on this solution to maintain filter integrity under rigorous operating conditions.

Sample Policy & Delivery for Antistatic Halar Coating Services

Experience our offering with available samples to assess service quality before your order commitment. Once the offer is accepted, goods are shipped promptly, and the typical delivery period is 3-7 days. We facilitate convenient exchanges for samples to ensure customer satisfaction. Each coated filter is protected with anti-scratch, dust-proof covers during transit, safeguarding the immaculate surface until you receive it.

Antistatic Halar Coating Services: Where Precision Meets Performance

Our coating services are indispensable across pharmaceutical, food processing, chemical, and electronics industries for their exemplary protection against static and corrosion. The process leverages advanced electrostatic spray machines with thermal curing, resulting in a smooth, uniform finish and impeccable adhesion. Special features include remarkable durability at temperatures up to 150C and strong performance on both metal and non-metal filters. Count on this solution to maintain filter integrity under rigorous operating conditions.

Sample Policy & Delivery for Antistatic Halar Coating Services

Experience our offering with available samples to assess service quality before your order commitment. Once the offer is accepted, goods are shipped promptly, and the typical delivery period is 3-7 days. We facilitate convenient exchanges for samples to ensure customer satisfaction. Each coated filter is protected with anti-scratch, dust-proof covers during transit, safeguarding the immaculate surface until you receive it.

FAQ's of Antistatic Halar Coating Services On Filters:

Q: How does the antistatic Halar coating benefit industrial filter applications?

A: The antistatic Halar coating prevents static buildup, offering enhanced safety and operational efficiency in sensitive environments such as pharmaceutical, electronics, and chemical processing plants.Q: What is the process for applying the Halar coating to filters?

A: The process involves preparing the filter surface by sandblasting or chemical cleaning, followed by electrostatic spray coating. The coated filters are then thermally cured at specified temperatures to ensure strong adhesion and an even finish.Q: When can I expect delivery of my coated filters?

A: Coated filters are typically shipped within 3-7 days after receipt of your order, ensuring a prompt turnaround without compromising on quality.Q: Where can these antistatic coating services be utilized?

A: These services are especially beneficial in industries where static control and chemical resistance are critical, such as pharmaceutical manufacturing, food processing, electronics assembly, and chemical plants.Q: What are the customization options for this coating service?

A: Coating thickness (20-120 microns), color (green or as required), and surface finish can be customized according to specific application requirements.Q: How long do the coated filters last under operating conditions?

A: The coated filters can maintain their performance and integrity for up to 5 years, depending on environmental conditions and usage.

Price 2000 INR/ Square Feet

- Minimum Order Quantity

- 1 Square Feet

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Halar Coating Services Category

Halar Coating Services On Stirrers

Price 1700 INR / Square Feet

Minimum Order Quantity : 1 Square Feet

Halar Coating Services On Centrifuge

Price 2000 INR / Square Feet

Minimum Order Quantity : 1 Square Feet