Halar Coating Services On Centrifuge

Halar Coating Services On Centrifuge Specification

- Compliance

- Meets industry and safety standards for coatings

- Coating Thickness

- Typically 0.2 mm to 1 mm (customizable)

- Life Expectancy

- Extends equipment life by preventing corrosion and chemical damage

- Application

- Industrial centrifuge surface protection

- Industries Served

- Pharmaceuticals, Chemicals, Food Processing, and Biotechnology

- Service Location

- On-site or off-site as per client requirement

- Abrasion Resistance

- High, suitable for rigorous centrifuge operation

- Adhesion

- Superior on metal substrate

- Corrosion Resistance

- Excellent against acids, alkalis, and solvents

- Product Name

- Halar Coating Services On Centrifuge

- Service Availability

- Pan India and export solutions

- Curing Process

- Controlled thermal curing ensures durable adhesion

- Surface Preparation

- Grit blasting and thorough cleaning prior to coating

- Environmental Impact

- Environmentally friendly, halogenated copolymer

- Temperature Resistance

- Up to 150C

- Coating Material

- Halar (ECTFE)

- Customizability

- Available for various centrifuge sizes and configurations

- Electrical Insulation

- Excellent dielectric properties

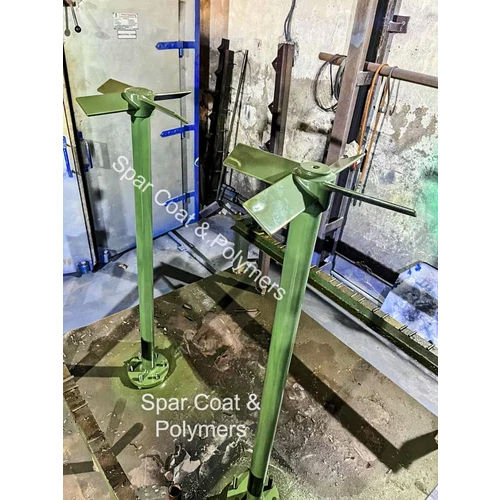

- Colour

- Green (standard Halar colour)

- Maintenance

- Minimal; easy to clean surface

- Finish

- Smooth, glossy, and non-porous

Halar Coating Services On Centrifuge Trade Information

- Minimum Order Quantity

- 1 Square Feet

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About Halar Coating Services On Centrifuge

Experience unassailable surface protection for your centrifuge with our Halar Coating Services, the renowned choice for high abrasion resistance and classic durability. Special rates are available, allowing you to personalise your coating requirements with savings in mind. The coating, crafted from Halar (ECTFE), excels in electrical insulation and corrosion resistance, while its environmentally friendly formulation meets rigorous industry and safety standards. Benefit from controlled curing, minimal maintenance, and customisable solutions for all centrifuge sizes. This service extends equipment life and ensures a smooth, non-porous green finish. Available pan India and for export.

Comprehensive Protection for Rigorous Centrifuge Operations

Halar Coating Services On Centrifuge are used to safeguard industrial centrifuges in demanding environments such as pharmaceuticals, food processing, chemicals, and biotechnology. The coating excels in surface protection, ensuring excellent resistance to acids, alkalis, abrasives, and solvents. Its application places range from small-scale research facilities to large-scale processing plants. This service offers optimal performance, extending equipment life by providing a robust and easily cleaned thermal-cured barrier.

Certified Quality, Domestic Reach, and Secure Packaging

Our Halar Coating Services On Centrifuge are certified to meet industry and safety standards, ensuring peace of mind with every application. Shipped securely across the main domestic and export markets, all coated equipment is meticulously packed to safeguard the finish during transit. The carefully considered outlay ensures maximum value with every job, providing renowned protection and reliability, whether you require pan-India delivery or overseas export solutions.

Comprehensive Protection for Rigorous Centrifuge Operations

Halar Coating Services On Centrifuge are used to safeguard industrial centrifuges in demanding environments such as pharmaceuticals, food processing, chemicals, and biotechnology. The coating excels in surface protection, ensuring excellent resistance to acids, alkalis, abrasives, and solvents. Its application places range from small-scale research facilities to large-scale processing plants. This service offers optimal performance, extending equipment life by providing a robust and easily cleaned thermal-cured barrier.

Certified Quality, Domestic Reach, and Secure Packaging

Our Halar Coating Services On Centrifuge are certified to meet industry and safety standards, ensuring peace of mind with every application. Shipped securely across the main domestic and export markets, all coated equipment is meticulously packed to safeguard the finish during transit. The carefully considered outlay ensures maximum value with every job, providing renowned protection and reliability, whether you require pan-India delivery or overseas export solutions.

FAQ's of Halar Coating Services On Centrifuge:

Q: How is the Halar coating applied to a centrifuge for maximum adhesion?

A: The process begins with grit blasting and thorough cleaning of the centrifuge surface to ensure optimal adhesion. This is followed by the precise application of Halar (ECTFE) and a controlled thermal curing cycle for maximum longevity and performance.Q: What benefits does Halar coating offer compared to traditional coatings?

A: Halar coating provides exceptional abrasion resistance, excellent dielectric properties, and superior corrosion protection against acids, alkalis, and solvents. It also offers a smooth, non-porous finish that is easy to clean and maintain, extending equipment lifespan significantly.Q: Can the Halar coating be personalised for different centrifuge sizes and configurations?

A: Yes, our service allows customisation for a variety of centrifuge sizes and operational setups, ensuring a tailored coating thickness (typically 0.2 mm to 1 mm) to best protect your specific equipment.Q: Where are your Halar Coating Services available?

A: We offer our Halar Coating Services both on-site and off-site, depending on your requirements. Our solutions are available pan-India and for international export.Q: What industries typically use Halar Coating Services On Centrifuge?

A: Industries served include pharmaceuticals, chemicals, biotechnology, and food processing-anywhere rigorous and reliable surface protection is required for centrifuge equipment.Q: How does the coating process support environmental and safety standards?

A: The Halar coating utilises an environmentally friendly, halogenated copolymer that complies with strict industry and safety standards, ensuring both worker safety and reduced environmental impact.

Price 2000 INR/ Square Feet

- Minimum Order Quantity

- 1 Square Feet

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Halar Coating Services Category

Halar Coating Services On Reciever

Price 2000 INR / Square Feet

Minimum Order Quantity : 1 Square Feet

Antistatic HALAR Coated Equipments Services

Price 2000 INR / Square Feet

Minimum Order Quantity : 1 Square Feet

Halar Coating Service on Centrifuge Basket

Price 1500 INR / Square Feet

Minimum Order Quantity : 1 Square Feet