XYLAN Coating Services On Stud

XYLAN Coating Services On Stud Specification

- Max Operating Temperature

- Up to 220C

- Service Type

- XYLAN Coating Services On Stud

- Coating Material

- XYLAN

- Color

- Blue

- Application Method

- Manual

- Coated Material

- Stud

- Finish Type

- Smooth, Non-Stick

- Average Service Duration

- 1-2 Days

- Type of Coating Process

- Spray Coating

- Usage/Application

- Industrial

- Location

- On Site

- Custom Coating Available

- Yes

- Film Thickness Range

- 25-40 Micron

- Surface Preparation

- Abrasive Blasting

- Curing Method

- Oven Baked

XYLAN Coating Services On Stud Trade Information

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1000 Square Inches Per Month

- Delivery Time

- 7 Days

About XYLAN Coating Services On Stud

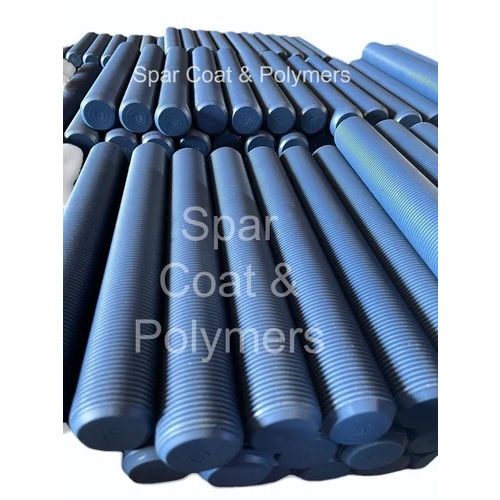

Capitalise on the latest innovations in surface technology with our XYLAN Coating Services On Stud. Designed for industrial excellence, this top-rated service offers a smooth, radiant, and non-stick finish with film thickness ranging from 25-40 microns. Best for applications requiring exceptional adhesion, our oven-baked process ensures a polished and durable blue coating that withstands temperatures up to 220C. Surface preparation by abrasive blasting and custom coatings guarantee optimal performance. Benefit from fast turnaround and superior quality from India's trusted manufacturer, supplier, and service provider.

Unmatched Industrial Protection Where You Need It

XYLAN Coating Services On Stud deliver site-specific application directly on-site, ensuring seamless integration within your industrial environment. Highlighted by its smooth finish and robust adhesion, this service excels in protecting studs across a wide range of applications such as petrochemical facilities, manufacturing plants, and critical machinery installations. Engineered for versatility, the process is manually applied and oven cured, supporting both standard and custom coating requirements, so your equipment operates at its radiant best regardless of conditions.

Expansive Reach and Reliable Supply Chain Assurance

Our XYLAN Coating Services On Stud cater to major export markets throughout Asia, the Middle East, and Africa, supported by high supply ability for both small and large scale orders. Clients benefit from transparent proposal amounts, efficient payment terms, and the option of express shipping for time-sensitive needs. Committed to order completion within an average service duration of just 1-2 days, we ensure your projects proceed without unnecessary delays, whether for ongoing maintenance or new installations.

Unmatched Industrial Protection Where You Need It

XYLAN Coating Services On Stud deliver site-specific application directly on-site, ensuring seamless integration within your industrial environment. Highlighted by its smooth finish and robust adhesion, this service excels in protecting studs across a wide range of applications such as petrochemical facilities, manufacturing plants, and critical machinery installations. Engineered for versatility, the process is manually applied and oven cured, supporting both standard and custom coating requirements, so your equipment operates at its radiant best regardless of conditions.

Expansive Reach and Reliable Supply Chain Assurance

Our XYLAN Coating Services On Stud cater to major export markets throughout Asia, the Middle East, and Africa, supported by high supply ability for both small and large scale orders. Clients benefit from transparent proposal amounts, efficient payment terms, and the option of express shipping for time-sensitive needs. Committed to order completion within an average service duration of just 1-2 days, we ensure your projects proceed without unnecessary delays, whether for ongoing maintenance or new installations.

FAQ's of XYLAN Coating Services On Stud:

Q: How does the XYLAN coating process work for studs?

A: The XYLAN coating service involves abrasive blasting for surface preparation, followed by manual spray application, oven baking for curing, and results in a smooth, non-stick blue finish offering excellent adhesion and protection.Q: What are the main benefits of XYLAN coating on studs?

A: XYLAN coating provides outstanding non-stick properties, a polished and radiant appearance, high resistance to chemicals and temperature up to 220C, as well as excellent adhesion and durability for industrial use.Q: Where can XYLAN coating services for studs be applied?

A: This service is particularly suited for industrial sectors such as petrochemical, manufacturing, and machinery installations where robust, long-lasting stud protection is required.Q: When can I expect order completion for XYLAN coating services?

A: Most XYLAN coating jobs are completed within 1-2 days, with express shipping options available to ensure prompt delivery and minimal downtime.Q: What export markets do you cover for XYLAN coating services?

A: We supply XYLAN coated studs to markets across Asia, the Middle East, and Africa, ensuring consistent quality and timely delivery for our international clients.Q: How is custom coating for studs managed?

A: Custom coatings are available and tailored to specific requirements, with each project reviewed and a proposal amount provided based on unique client needs.

Price 3 INR/ Square Inch

- Minimum Order Quantity

- 1 Square Inch

- Supply Ability

- 1000 Square Inches Per Month

- Delivery Time

- 7 Days

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in XYLAN Coating Service Category

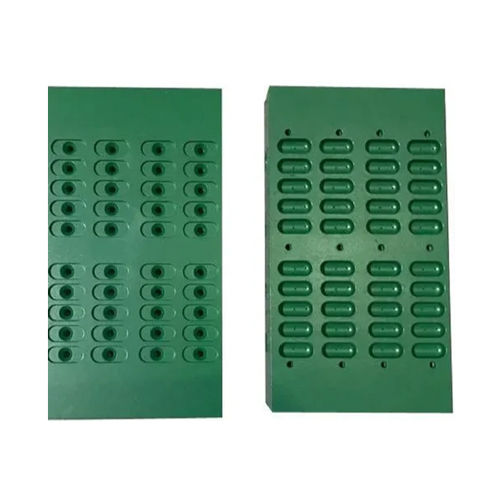

PTFE XYLAN Coating Services On Dyes and Mould

Price 2.5 INR / Square Inch

Minimum Order Quantity : 1 Square Inch

XYLAN Coating Services On Piston

Price 2000 INR / Square Feet

Minimum Order Quantity : 1 Square Feet

PTFE XYLAN Coating Services On Bolt

Price 2 INR / Square Inch

Minimum Order Quantity : 1 Square Inch