मà¥à¤²à¥à¤¡à¥à¤¸ पर XYLAN à¤à¥à¤à¤¿à¤à¤ सà¥à¤µà¤¾à¤à¤

मà¥à¤²à¥à¤¡à¥à¤¸ पर XYLAN à¤à¥à¤à¤¿à¤à¤ सà¥à¤µà¤¾à¤à¤ Specification

- Custom Coating Available

- Yes, as per clientâs specifications

- Life Expectancy

- Depends on mold use and maintenance, generally 8-12 months

- Temperature Resistance

- Up to 285°C

- Service Mode

- Offline and Site Application

- Coating Type

- XYLAN (PTFE based) Coating

- Usage

- Industrial mold protection and release

- Coated Material Supported

- Metal mold substrates

- Curing Time

- Varies by coating; generally 30-60 minutes at 200°C

- Color Options

- Blue, Green, Black (custom on request)

- Coating Purpose

- Corrosion resistance and non-stick surface

- Application Method

- Spray and oven cured

- Adhesion Strength

- Excellent; designed for high-cycle tooling

- Surface Preparation

- Degreasing, Grit Blasting, Cleaning

- Service Location

- Onsite / Offsite as required

- Release Performance

- Superior nonstick, easy demolding of parts

- Coating Thickness

- Typically 15-40 microns

- Chemical Resistance

- High resistance to chemicals and solvents

मà¥à¤²à¥à¤¡à¥à¤¸ पर XYLAN à¤à¥à¤à¤¿à¤à¤ सà¥à¤µà¤¾à¤à¤ Trade Information

- Minimum Order Quantity

- 1 Square Inch

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About मà¥à¤²à¥à¤¡à¥à¤¸ पर XYLAN à¤à¥à¤à¤¿à¤à¤ सà¥à¤µà¤¾à¤à¤

Unlock instant savings and protect your molds with our sizzling XYLAN Coating सेवाएं, featuring immaculate PTFE-based coverage for demanding industrial needs. This terrific promotion ensures your metal molds receive a gorgeous, flawless finish-spray applied and oven-cured for superior adhesion and chemical resistance. Our process includes meticulous degreasing, grit blasting, and cleaning, followed by oven curing at 200C for 30-60 minutes. Benefit from excellent release performance, enduring 8-12 months with custom options available, and choose from blue, green, or black finishes. Serving all over India as a top manufacturer, supplier, and service provider!

Features and Applications of XYLAN Coating सेवाएं

XYLAN Coating सेवाएं on molds are predominantly used for providing superb corrosion resistance and a non-stick surface. Perfect for industrial settings, these coatings are applied to metal mold substrates using a spray and oven curing process. Key application areas include automotive, packaging, and plastic industries, ensuring superior release performance and protection. With excellent chemical resistance, customizable options, and a life expectancy of 8 to 12 months, this service is ideal for high-cycle tooling and demanding operational environments.

XYLAN Coating सेवाएं: Sample Policy, Export Market, and Payment

Clients seeking immaculate coatings can benefit from our transparent sample policy. Sample outlay details are provided upon request, and we often have stock ready for quick demonstrations. Our main export markets comprise Europe, the USA, and the Middle East. Secure shipment is arranged post-order confirmation, and we offer flexible payment terms suited to varied business needs, ensuring a seamless transaction and swift delivery of our sizzling coating services worldwide.

Features and Applications of XYLAN Coating सेवाएं

XYLAN Coating सेवाएं on molds are predominantly used for providing superb corrosion resistance and a non-stick surface. Perfect for industrial settings, these coatings are applied to metal mold substrates using a spray and oven curing process. Key application areas include automotive, packaging, and plastic industries, ensuring superior release performance and protection. With excellent chemical resistance, customizable options, and a life expectancy of 8 to 12 months, this service is ideal for high-cycle tooling and demanding operational environments.

XYLAN Coating सेवाएं: Sample Policy, Export Market, and Payment

Clients seeking immaculate coatings can benefit from our transparent sample policy. Sample outlay details are provided upon request, and we often have stock ready for quick demonstrations. Our main export markets comprise Europe, the USA, and the Middle East. Secure shipment is arranged post-order confirmation, and we offer flexible payment terms suited to varied business needs, ensuring a seamless transaction and swift delivery of our sizzling coating services worldwide.

FAQ's of XYLAN Coating सेवाएं On Moldes:

Q: How does the XYLAN coating process improve mold performance?

A: XYLAN coating enhances mold performance by providing outstanding non-stick properties, high chemical resistance, and excellent corrosion protection. This results in easy demolding, extended tool life, and reduced downtime during manufacturing cycles.Q: What is the typical process for applying XYLAN Coating on molds?

A: The application involves degreasing, grit blasting, and cleaning the mold surface, followed by spraying the XYLAN coating and oven curing at 200C for 30-60 minutes. This ensures superior adhesion and coating integrity.Q: Where can XYLAN Coating सेवाएं be applied?

A: These services are suitable for industrial settings, especially where metal mold substrates are used-such as automotive, packaging, and plastics manufacturing industries needing corrosion resistance and efficient part release.Q: When is it advisable to reapply the XYLAN coating?

A: It is recommended to reapply the coating every 8 to 12 months, depending on the level of mold usage and the maintenance practices in place, to maintain optimal performance and protection.Q: What are the benefits of choosing custom XYLAN coating specifications?

A: Custom specifications allow clients to select thickness, color, and other properties according to their operational requirements, optimizing performance for particular mold applications and unique production environments.

Price 2 आईएनआर/ Square Inch

- Minimum Order Quantity

- Supply Ability

- Delivery Time

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in XYLAN कोटिंग सेवा Category

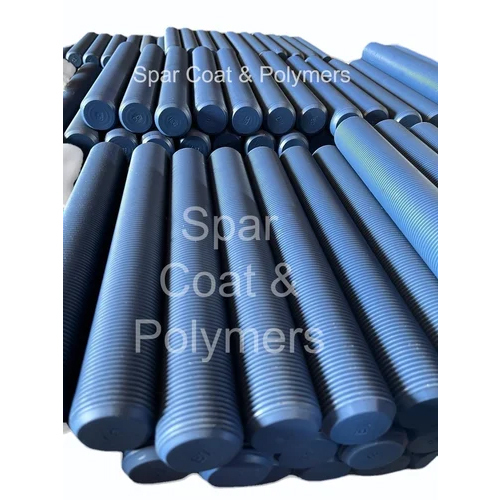

स्टड पर XYLAN कोटिंग सेवाएँ

मूल्य की इकाई : Square Inch/Square Inches

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Inch/Square Inches

सीलिंग ब्लेड पर XYLAN कोटिंग सेवाएं

मूल्य की इकाई : Square Inch/Square Inches

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Inch/Square Inches

फास्टनर XYLAN कोटिंग सेवाएँ

मूल्य की इकाई : Square Inch/Square Inches

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Inch/Square Inches

नट पर PTFE XYLAN कोटिंग सेवाएँ

मूल्य की इकाई : Square Inch/Square Inches

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Inch/Square Inches