सà¥à¤à¥à¤°à¥à¤ वà¥à¤¸à¤² पर हà¥à¤²à¤° à¤à¤° à¤à¤¸à¥à¤à¥à¤à¤«à¤ à¤à¥à¤à¤¿à¤à¤

सà¥à¤à¥à¤°à¥à¤ वà¥à¤¸à¤² पर हà¥à¤²à¤° à¤à¤° à¤à¤¸à¥à¤à¥à¤à¤«à¤ à¤à¥à¤à¤¿à¤à¤ Specification

- Product

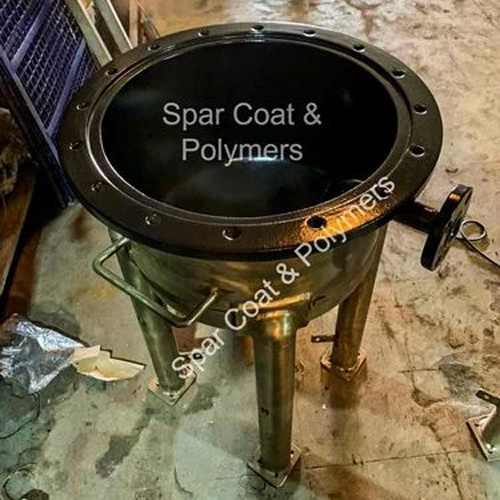

- Halar and ECTFE Coating on Storage Vessel

- Chemical Resistance

- Excellent against acids, alkalis, solvents, and brine solutions

- Storage Vessel Size

- Custom fabrication as required

- Corrosion Protection

- Excellent resistance to corrosion and UV degradation

- Electrical Properties

- High Dielectric Strength

- Application Method

- Electrostatic Spray Coating followed by Thermal Curing

- Permeability

- Extremely low permeability to gases and liquids

- Adhesion

- Superior adhesion to metallic substrates

- Mechanical Strength

- Retains high impact strength even at low temperatures

- Custom Options

- Available in different coating thicknesses, finishes, and vessel shapes per requirement

- Surface Finish

- Smooth, semi-glossy

- Base Material

- Mild Steel, Stainless Steel, or Specified Alloy

- Typical Use

- Chemical processing, pharmaceutical, petrochemical, and food industries

- Maximum Operating Pressure

- As per vessel design and construction norms

- Water Absorption

- Less than 0.04% at room temperature

- Temperature Resistance

- Up to 150°C

- Flame Retardancy

- Self-extinguishing as per UL 94 V-0

- Compliance

- ASTM, FDA, and other industrial standards

- Color

- Typically pale green (Halar)

- Environmental Stability

- Resistant to weathering and harsh outdoor conditions

- Coating Material

- Halar (ECTFE) â Ethylene Chlorotrifluoroethylene

- Sealing Capability

- Leakproof coating prevents contamination

- Abrasion Resistance

- High â suitable for aggressive environments

- Maintenance

- Low, easy to clean surface

- Coating Thickness

- 300-1200 Micron (as per requirement)

सà¥à¤à¥à¤°à¥à¤ वà¥à¤¸à¤² पर हà¥à¤²à¤° à¤à¤° à¤à¤¸à¥à¤à¥à¤à¤«à¤ à¤à¥à¤à¤¿à¤à¤ Trade Information

- Minimum Order Quantity

- 1 Square Feet

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About सà¥à¤à¥à¤°à¥à¤ वà¥à¤¸à¤² पर हà¥à¤²à¤° à¤à¤° à¤à¤¸à¥à¤à¥à¤à¤«à¤ à¤à¥à¤à¤¿à¤à¤

Advance Purchase our top-rated Halar and ECTFE Coating on Storage Vessel for unassailable chemical and abrasion resistance, pivotal in aggressive industrial environments. Engineered with top-notch electrostatic spray coating and thermal curing, this solution boasts exceptionally low water absorption (less than 0.04%), leakproof sealing, superior flame retardancy (self-extinguishing UL 94 V-0), and high dielectric strength. Permeability to gases and liquids is extremely low, ensuring optimal storage conditions. Pick Yours with custom options in thickness, vessel shape, and finish, meeting ASTM, FDA, and other pivotal compliance standards. Ideal for industries requiring corrosion, UV, and impact protection-even in the harshest settings

Versatile Industrial Protection for Critical Applications

Halar and ECTFE Coating on Storage Vessels are used for protecting valuable contents in chemical processing, pharmaceutical, petrochemical, and food industries. Suitable for use where maximum abrasion, corrosion, and chemical resistance are pivotal, these vessels serve as unassailable barriers against aggressive agents. Used as primary storage for acids, solvents, alkalis, and sensitive substrates, they ensure longevity and contamination-free operation in demanding environments-guaranteeing reliability where it matters most.

Seamless Delivery and Secure Packaging Solutions

Packing & Dispatch services focus on maintaining the integrity of each storage vessel. Goods Transport is managed through reliable logistics partners to ensure timely and safe delivery. Depending on the specifics of your Purchase Order, standard delivery times and customized packaging options are provided. Securely packed as per industry norms, vessels reach you in optimal condition. Sample Policy details are available upon request for clients seeking quality assurance before placing bulk orders.

Versatile Industrial Protection for Critical Applications

Halar and ECTFE Coating on Storage Vessels are used for protecting valuable contents in chemical processing, pharmaceutical, petrochemical, and food industries. Suitable for use where maximum abrasion, corrosion, and chemical resistance are pivotal, these vessels serve as unassailable barriers against aggressive agents. Used as primary storage for acids, solvents, alkalis, and sensitive substrates, they ensure longevity and contamination-free operation in demanding environments-guaranteeing reliability where it matters most.

Seamless Delivery and Secure Packaging Solutions

Packing & Dispatch services focus on maintaining the integrity of each storage vessel. Goods Transport is managed through reliable logistics partners to ensure timely and safe delivery. Depending on the specifics of your Purchase Order, standard delivery times and customized packaging options are provided. Securely packed as per industry norms, vessels reach you in optimal condition. Sample Policy details are available upon request for clients seeking quality assurance before placing bulk orders.

FAQ's of Halar And ECTFE Coating On Storage Vessel:

Q: How does Halar and ECTFE coating benefit storage vessels in aggressive environments?

A: The Halar and ECTFE coating provides robust abrasion, chemical, and UV resistance, ensuring unassailable protection of storage vessels used in harsh, aggressive environments.Q: What is the process for applying Halar and ECTFE coatings to vessels?

A: The coating is applied using an electrostatic spray technique followed by thermal curing, creating a top-notch, seamless layer that adheres superbly to metallic substrates.Q: When can I expect delivery after placing a purchase order?

A: Delivery timelines depend on the vessel's customization and size but are confirmed at the time of purchase order acknowledgment, ensuring clear communication on your order status.Q: Where are Halar and ECTFE coated vessels commonly used?

A: These vessels are widely used in chemical processing plants, pharmaceutical facilities, petrochemical sectors, and food industries requiring strict contamination control.Q: How does the coating maintain storage vessel integrity over time?

A: Halar and ECTFE coatings offer high environmental stability, resisting weathering, impact, chemical exposure, and temperature cycles to maintain vessel performance and longevity.Q: What are the maintenance requirements for coated storage vessels?

A: The low-maintenance, easy-to-clean surface ensures minimal upkeep, making these vessels an efficient and cost-effective solution for rigorous industrial applications.

Price 2000 आईएनआर/ Square Feet

- Minimum Order Quantity

- Supply Ability

- Delivery Time

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in ECTFE कोटिंग सेवाएँ Category

औद्योगिक हलार इक्टफे कोटिंग सेवाएं

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Feet

मूल्य की इकाई : Square Feet

औद्योगिक ECTFE कोटिंग सेवाएँ

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Feet

मूल्य की इकाई : Square Feet

सेंट्रीफ्यूज बास्केट पर ECTFE कोटिंग सेवाएं

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Feet

मूल्य की इकाई : Square Feet

पाइप्स पर हैलर इक्टफे कोटिंग सेवाएं

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 1

माप की इकाई : Square Feet

मूल्य की इकाई : Square Feet