Etfe Coating Service

Etfe Coating Service Specification

- Non-stick Properties

- High non-stick effectiveness

- Coating Material

- ETFE (Ethylene Tetrafluoroethylene)

- Temperature Resistance

- Up to 150C

- Corrosion Protection

- Offers superior corrosion resistance

- Service Location

- On-site and Off-site

- UV Resistance

- High resistance to UV radiation

- Coating Thickness

- 10 to 100 microns

- Application Surface

- Metal, Concrete, Plastics, Glass

- Flame Retardant

- Meets fire safety standards

- Environmental Compatibility

- Low VOC emission, eco-friendly process

- Service Type

- ETFE Coating Service

- Color Options

- Translucent and available in various colors

- Electrical Insulation

- Excellent dielectric properties

- Service Mode

- Offline

- Finish

- Smooth, glossy

- Usage/Application

- Industrial protective coating

- Chemical Resistance

- Excellent against acids, bases, solvents

- Adhesion Strength

- Strong adhesion to multiple substrates

Etfe Coating Service Trade Information

- Minimum Order Quantity

- 1 Square Feet

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Etfe Coating Service

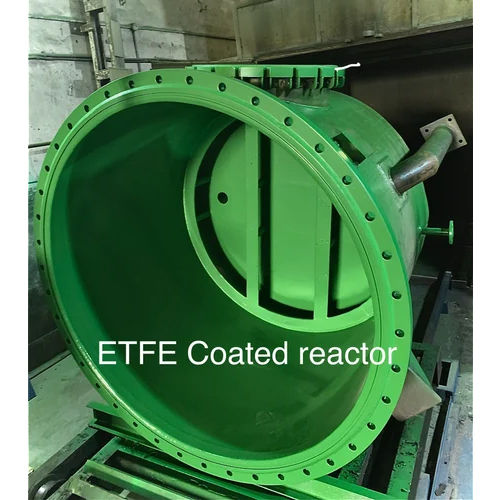

Illuminate your industrial assets with our gilt-edged ETFE Coating Service, featuring immaculate adhesion to metals, glass, plastics, and concrete. Instantly redeem superior performance with dazzling corrosion protection, exceptional non-stick effectiveness, and robust UV and flame resistance. This eco-friendly, low VOC process secures a smooth, glossy finish in a choice of translucent or vibrant shades. Designed for temperatures up to 150C and outstanding chemical resistance, our featured coating service is available for both on-site and off-site applicationstailored for manufacturers, suppliers, and traders across India. Experience instant checkout and elevate your facility protection.

Advanced ETFE Coating Applications for Industrial Protection

Our ETFE Coating Service is engineered for demanding industrial plant environments, offering flawless protection for machinery, tanks, ducts, and equipment. Noted for its strong adhesion and immaculate finish, the service is ideal for use in manufacturing plants and chemical industries. Extra features include high dielectric strength, corrosion resistance, and a dazzling spectrum of color options, ensuring your infrastructure remains resilient and visually appealing. Opt for this gilt-edged solution to maximize equipment longevity and operational reliability.

Packaging, Sample Availability, and Sale Price Details

We package ETFE Coating Service to ensure product safety and pristine delivery, whether on-site or off-site. Sample coatings are available by request, allowing you to inspect finish and performance before full expenditure. Our competitive sale price structure aligns with service volume and specifics, with transparent charge details provided at quote. With robust supply ability, we efficiently serve orders across multiple sectors, minimizing your procurement expenditure while guaranteeing consistent, high-quality results.

Advanced ETFE Coating Applications for Industrial Protection

Our ETFE Coating Service is engineered for demanding industrial plant environments, offering flawless protection for machinery, tanks, ducts, and equipment. Noted for its strong adhesion and immaculate finish, the service is ideal for use in manufacturing plants and chemical industries. Extra features include high dielectric strength, corrosion resistance, and a dazzling spectrum of color options, ensuring your infrastructure remains resilient and visually appealing. Opt for this gilt-edged solution to maximize equipment longevity and operational reliability.

Packaging, Sample Availability, and Sale Price Details

We package ETFE Coating Service to ensure product safety and pristine delivery, whether on-site or off-site. Sample coatings are available by request, allowing you to inspect finish and performance before full expenditure. Our competitive sale price structure aligns with service volume and specifics, with transparent charge details provided at quote. With robust supply ability, we efficiently serve orders across multiple sectors, minimizing your procurement expenditure while guaranteeing consistent, high-quality results.

FAQs of Etfe Coating Service:

Q: How does ETFE coating provide superior corrosion and chemical resistance?

A: ETFE coatings create a seamless, non-porous barrier that effectively shields substrates from harsh chemicals, acids, and bases, delivering long-lasting corrosion resistance in industrial environments.Q: What is the process for applying ETFE coating to industrial surfaces?

A: Our process involves thorough surface preparation, followed by precision spraying of ETFE material, achieving uniform thickness (10100 microns) for optimal adhesion and performance on metals, concrete, plastics, and glass.Q: Where can the ETFE coating service be utilized?

A: ETFE coating is highly versatile and can be used on plant equipment, tanks, pipelines, ducts, and various industrial infrastructure, offering protection in sectors such as manufacturing, chemicals, and energy.Q: When can I request samples and what are the supply details?

A: Samples are available prior to placing your full order; simply contact our support team. We maintain a strong supply capacity to fulfill orders promptly across India, both on-site and off-site.Q: What are the main benefits of choosing your ETFE Coating Service?

A: Clients benefit from a dazzling finish, immaculate protection, strong adhesion, low environmental impact, and the assurance of fire safety complianceall at a competitive sale price.

Price 2000 INR/ Square Feet

- Minimum Order Quantity

- 1 Square Feet

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in ETFE Tefzel Coating Services Category

PFA Coating Services On Equipments

Price 12000 INR / Square Foot

Minimum Order Quantity : 1 Square Foot